Why Wood Pulp is Essential for Sustainable Paper Production and Its Impact

In the realm of sustainable paper production, the role of wood pulp is paramount. As an essential raw material, wood pulp not only serves as the foundation of the paper industry but also plays a critical role in promoting environmentally friendly practices. According to Dr. Emily Johnson, a leading expert in forestry and sustainable materials, "Wood pulp is not just a fiber source; it is a catalyst for innovation in sustainable manufacturing." This underscores the idea that the production of paper can coexist with the preservation of our forests when managed responsibly.

The reliance on wood pulp does not equate to the depletion of natural resources. In fact, sustainable practices in the forestry sector and advancements in wood pulp processing have paved the way for a more circular economy. By integrating sustainable wood sourcing and recycling processes, the paper industry can mitigate its environmental footprint, ensuring that the production aligns with ecological principles. This evolving perspective positions wood pulp as a vital component in the pursuit of a greener, more sustainable future for the paper industry and the planet alike.

In conclusion, as we delve deeper into the intricate relationship between wood pulp and sustainable paper production, it is vital to recognize the implications of our choices. The commitment to utilizing wood pulp responsibly can lead to a significant impact on environmental sustainability, creating a model that serves both economic and ecological interests.

The Role of Wood Pulp in Sustainable Paper Production

Wood pulp plays a pivotal role in sustainable paper production, serving as the primary raw material for paper manufacturing. Its contribution extends beyond merely providing the fibrous content necessary for paper; it also supports environmentally-friendly practices. By utilizing sustainably sourced wood pulp from managed forests, the paper industry can significantly reduce its carbon footprint. This approach not only preserves biodiversity but also ensures that the ecosystems remain intact, balancing industrial needs with environmental stewardship.

Moreover, advancements in processing technologies for wood pulp have enhanced its sustainability profile. Techniques such as enzymatic treatments and recycling processes decrease waste and energy consumption during paper production. The ability to produce high-quality paper from recycled wood pulp further emphasizes the importance of renewable resources in this industry. As companies commit to sustainable practices, the use of wood pulp derived from responsibly managed forests ensures that their supply chains are not only efficient but also contribute to the long-term health of our planet.

Why Wood Pulp is Essential for Sustainable Paper Production and Its Impact

| Dimension | Description | Impact on Sustainability |

|---|---|---|

| Renewable Resource | Wood pulp is derived from trees, which are renewable resources when managed sustainably. | Supports sustainable forestry practices and reduces dependency on non-renewable materials. |

| Carbon Footprint | Wood pulp production has a lower carbon footprint compared to synthetic alternatives. | Mitigates climate change effects and enhances carbon sequestration in forests. |

| Biodegradability | Papers made from wood pulp are biodegradable and compostable. | Reduces landfill waste and promotes nutrient cycling in ecosystems. |

| Water Usage | Wood pulp production requires significant water resources. | Promotes the need for efficient water use and recycling in production processes. |

| Social Impact | Sustainable forest management practices support local communities and economies. | Encourages job creation and sustainable livelihoods in forestry-dependent regions. |

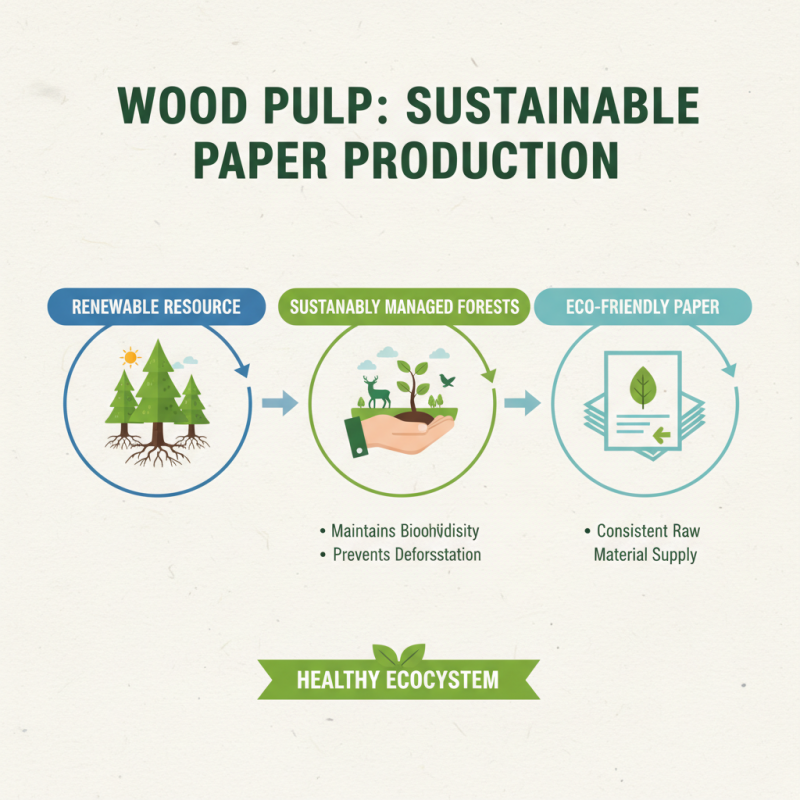

Environmental Benefits of Using Wood Pulp for Paper

Wood pulp plays a vital role in sustainable paper production due to its significant environmental benefits. One of the primary advantages of using wood pulp is that it is a renewable resource, especially when sourced from sustainably managed forests. These forests are carefully managed to maintain biodiversity and prevent deforestation, ensuring that the ecosystem remains healthy while providing a consistent supply of raw materials for paper manufacturing.

Moreover, the production of paper from wood pulp has a lower carbon footprint compared to alternatives such as recycled paper and synthetic fibers. Wood pulp production often utilizes advanced technologies that minimize energy consumption and reduce greenhouse gas emissions. Additionally, the use of wood pulp can contribute to carbon sequestration; forests absorb CO2, thereby offsetting emissions during the paper production process. This illustrates how responsibly sourced wood pulp not only supports the paper industry but also contributes positively to global environmental efforts.

Economic Impact of Wood Pulp on the Paper Industry

The economic impact of wood pulp on the paper industry is profound, particularly in the context of recent trade tensions and tariffs. For instance, the U.S. has implemented substantial tariffs on imports from major suppliers like Brazil, threatening to disrupt global pulp markets.

According to industry reports, these tariffs could lead to a rise in pulp prices and complicate supply chain dynamics, particularly for regions that rely heavily on imported materials. This economic pressure may force pulp producers to pass costs onto buyers, thereby affecting the pricing landscape of the entire sector.

Moreover, the resilience of the pulp and paper industry hinges on sustainable practices and innovative alternatives. Recent research has highlighted the potential for utilizing grass biomass as a substitute for traditional wood pulp, which not only diversifies raw material sources but also promotes environmental sustainability. Reports indicate that emerging economies are increasingly participating in the pulp and paper market, further affecting global supply and trade arrangements. As the sector transitions to more responsible practices, the adoption of eco-friendly forest management and alternative materials will become vital for maintaining economic viability while supporting sustainable development.

Tips:

- When assessing suppliers, consider their adherence to sustainable practices to ensure long-term viability.

- Stay informed on global trade policies, as they can significantly impact pricing and availability in the pulp and paper market.

- Explore alternative materials, such as grass pulp, which can help diversify sourcing and reduce environmental impact.

Innovative Practices in Wood Pulp Harvesting and Production

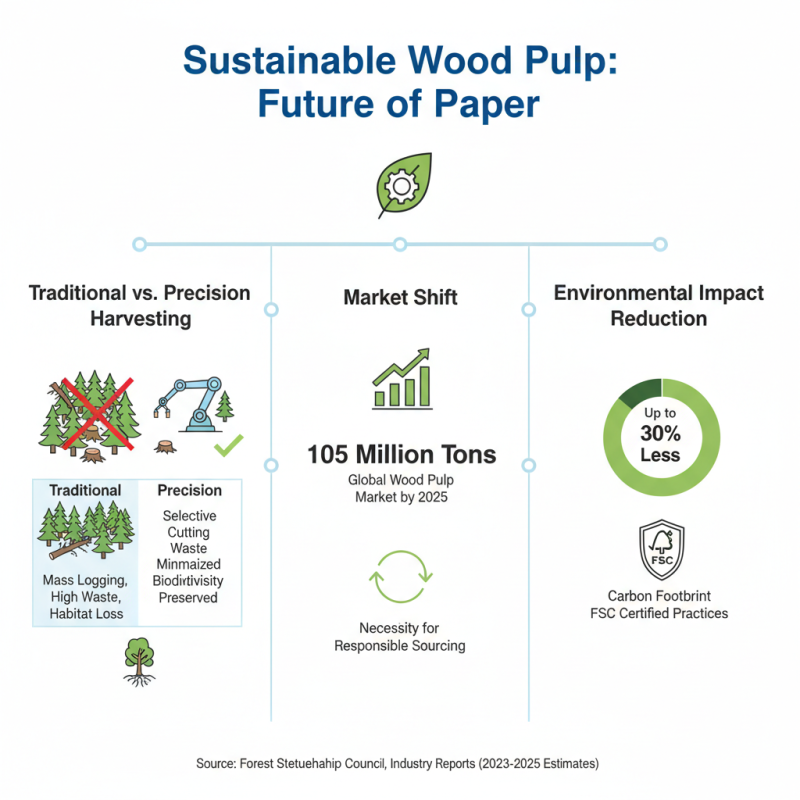

Innovative practices in wood pulp harvesting and production are pivotal in promoting sustainable paper manufacturing. Recent statistics indicate that the global market for wood pulp is projected to reach 105 million tons by 2025, underscoring the necessity for responsible sourcing methods. One emerging practice is the use of precision harvesting technology, which allows for selective logging of trees, minimizing waste and preserving biodiversity within forests. Reports from the Forest Stewardship Council (FSC) highlight that companies employing these techniques can reduce their environmental footprint by up to 30%.

Additionally, the implementation of alternative fibers, such as bamboo and agricultural residues, complements traditional wood pulp practices. The Paper and Packaging Board has documented a rising trend, noting that 20% of the paper produced in North America now sources alternative fibers. This diversification not only mitigates deforestation but also fosters innovation within the industry, allowing for a more resilient supply chain.

**Tip:** When seeking to support sustainable paper products, look for certifications like FSC or PEFC. These labels signify that the wood pulp used in the paper is sourced responsibly, contributing to sustainable forestry efforts. By choosing certified products, consumers can directly influence eco-friendly practices in the paper industry.

Future Trends in Sustainable Paper Production with Wood Pulp

The sustainable paper production landscape is evolving, driven by increasing consumer preference for eco-friendly materials and advancements in manufacturing technologies. According to industry forecasts, the global pulp and paper machinery market is expected to grow from $31.2 billion in 2023 to an estimated $40.8 billion by 2032, representing a compound annual growth rate (CAGR) of 3.9%. This trend highlights the critical role of wood pulp, as it remains the primary source for producing high-quality paper products while supporting sustainable practices.

In the context of market demands, the paper-based products catalog is projected to reach a value of $2.5 billion by 2024, with a CAGR surpassing 5.3% between 2025 and 2034. This growth is primarily fueled by a rising preference for tangible media among consumers. As industries increasingly embrace responsible forestry practices, the reliance on wood pulp will likely intensify, reinforcing its status as a cornerstone in the realm of sustainable packaging solutions.

**Tip:** Businesses seeking to thrive in this competitive market should prioritize sustainable sourcing methods and invest in innovative technologies that enhance the efficiency of wood pulp utilization. This approach not only reduces the environmental footprint but also meets the growing consumer demand for responsibly produced paper products. Staying informed about regulatory advancements in the industry will further bolster sustainable practices.

Wood Pulp Usage in Sustainable Paper Production

This bar chart illustrates the percentage usage of wood pulp, recycled paper, and alternative fibers in sustainable paper production for the year 2023. It highlights the critical role of wood pulp in the industry while also showcasing the importance of recycling and exploring alternative materials to promote sustainability.

Related Posts

-

How to Choose the Right Wood Pulp for Your Paper Production Needs

-

Understanding the Benefits of Hollow Fiber Membrane Filters for Water Purification

-

Emerging Trends in Best Pulp Industries to Watch for Global Buyers in 2025

-

Ultimate Guide to Choosing the Right Bagasse Plate Making Machine for Your Business

-

Understanding the Evolution of Pulp Molding Machines: A Deep Dive into Their Types and Applications

-

Enhancing After-Sales Service: Unmatched Repair Costs with the Best Filtration Technology