Comprehensive Guide to Microfiltration Membrane Technology: Key Applications and Performance Insights

Microfiltration membrane technology has emerged as a vital solution for various industries, particularly in enhancing water quality and efficiency in numerous processes. As reported by the Global Water & Wastewater Treatment Market Report, the demand for microfiltration membranes is expected to surpass USD 2.6 billion by 2027, driven primarily by the increasing need for clean water and effective wastewater treatment solutions. This technology operates on the principle of physical separation, effectively removing particles and pathogens from liquids while allowing the passage of smaller molecules. Its applications span across sectors such as food and beverage, pharmaceuticals, and environmental engineering, making it indispensable for meeting stringent regulatory standards and improving operational performance. As industries continue to prioritize sustainability and quality, understanding the nuances of microfiltration membrane performance and its key applications becomes crucial in driving innovations and investments in this field.

Introduction to Microfiltration Membrane Technology and Its Importance

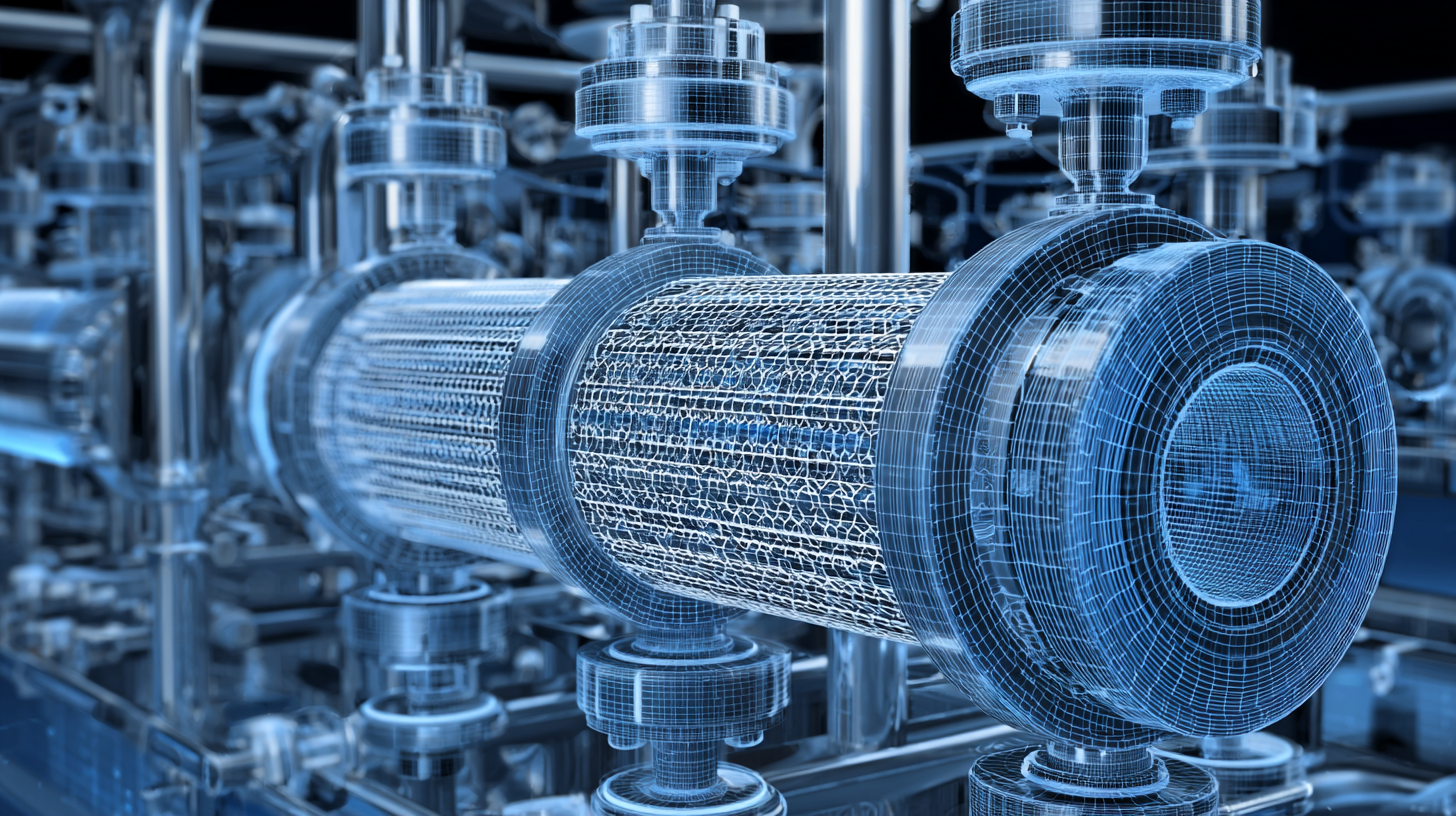

Microfiltration membrane technology has emerged as a powerful tool in various sectors, particularly in water treatment and industrial applications. Its importance lies in its ability to separate particles, microbes, and colloids from liquids, ensuring high-quality outputs and compliance with strict environmental regulations. Recent advancements have shed light on the mechanisms of membrane fouling, specifically the roles of protein characteristics and membrane interactions. Understanding these factors is crucial for optimizing performance.

Tips: When designing a microfiltration system, consider using predictive modeling to anticipate fouling behaviors. Incorporating a one-dimensional convolutional model can provide valuable insights into the relationships between membrane properties and fouling agents, allowing for more tailored solutions. Additionally, exploring hybrid systems, such as integrating biological processes with microfiltration, can significantly enhance treatment efficiency, particularly for complex wastewater streams.

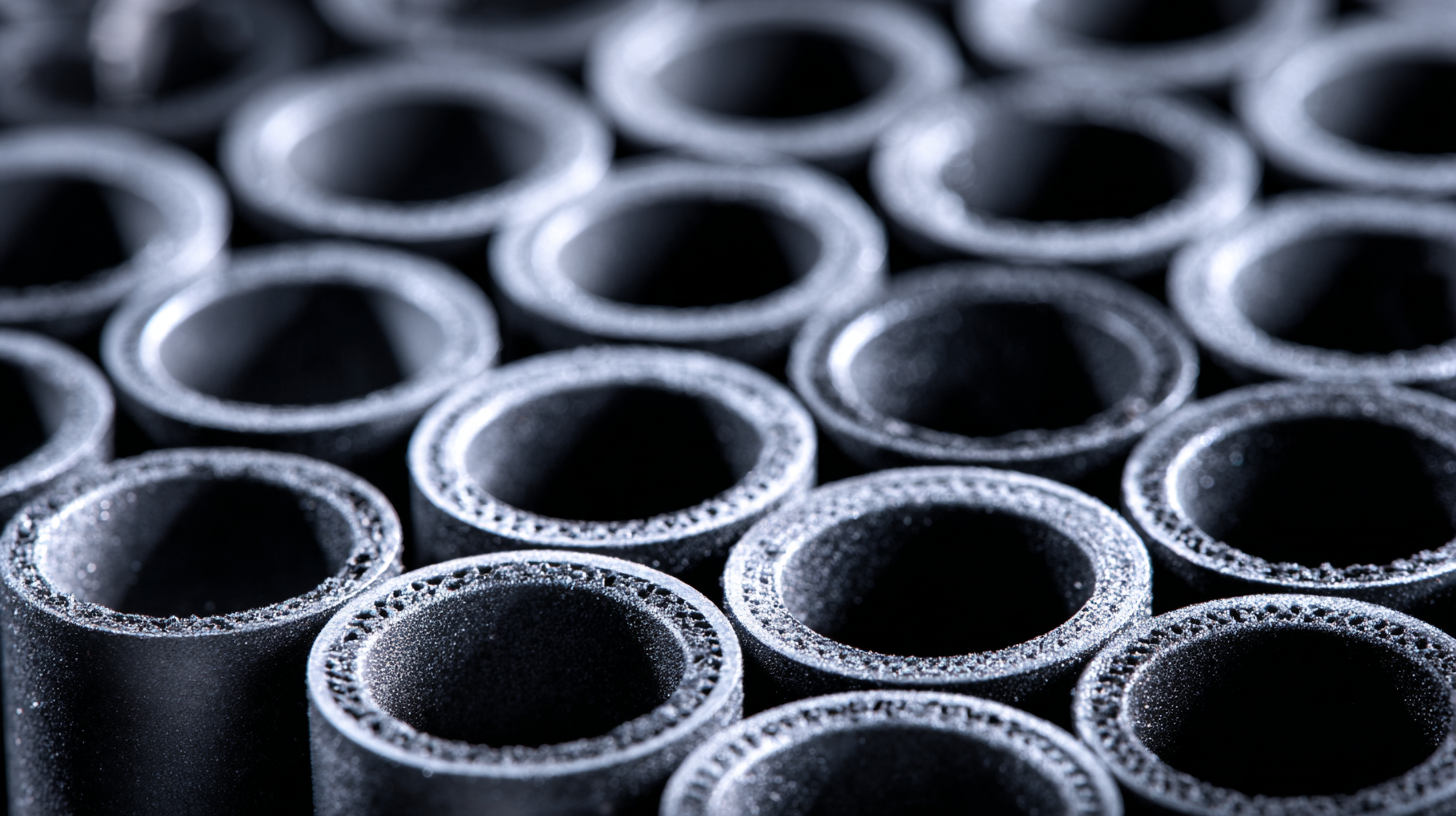

Another recent innovation in the field has been the development of alumina ceramic membranes, which demonstrate promise for water purification applications. These membranes are not only robust but also effective in reducing fouling through strategic design choices. Keep an eye on ongoing research for the latest strategies that could influence the future of microfiltration technologies.

Key Applications of Microfiltration in Water and Wastewater Treatment

Microfiltration (MF) and ultrafiltration (UF) are becoming increasingly popular in water and wastewater treatment, particularly within the food and beverage industry. These technologies provide effective means of separating impurities while ensuring the quality of the treated water meets stringent health standards. In municipal water treatment, MF and UF play vital roles in enhancing water clarity and removing pathogens, thereby contributing to safer drinking water supplies. The deployment of these filtration systems is paramount in optimizing operational efficiency and sustainability.

The oil and gas industry also benefits significantly from microfiltration and ultrafiltration systems. These applications aid in the treatment of produced water and wastewater, enabling the safe discharge back into the environment or recycling for reuse, which is becoming crucial in an era of heightened environmental regulations. Furthermore, the introduction of reverse osmosis (RO) technology complements these processes, allowing for a comprehensive approach to treating highly contaminated water sources across various sectors.

With the evolution of ecological initiatives, particularly in light of China’s commitment to green development post-19th National Congress, the water treatment sector is poised for innovative transformations. Advances in membrane technology, coupled with strategic management and cooperative frameworks, will shape a future where efficient wastewater treatment processes contribute to overall environmental sustainability.

Performance Metrics: Evaluating the Efficacy of Microfiltration Membranes

Microfiltration membranes are gaining attention for their performance in various applications, particularly in the removal of microplastics and bacterial contaminants. Recent studies have highlighted the efficacy of simple and low-cost filtration systems that utilize these membranes to achieve significant reductions in microplastic concentrations. By focusing on straightforward designs, these systems can be easily adopted in domestic settings, providing a practical solution for a growing environmental concern.

Moreover, advancements in membrane technology have led to the development of novel composite membranes that enhance bacterial filtration capabilities while retaining critical DNA components, illustrating their utility in medical and research applications. The evolution of membrane configurations, such as multistage approaches, further optimizes processes for industries like dairy, significantly improving efficiency in concentrating and fractionating milk and whey. As the performance of microfiltration membranes continues to improve, we are likely to see broader adoption across various sectors, driven by the need for effective and economical filtration solutions.

Innovations in Microfiltration Technology: Enhancements and Trends

Microfiltration membrane technology has seen significant innovations in recent years, driven by the demand for more efficient and sustainable filtration solutions across various industries. One of the most noteworthy advancements is the development of membrane materials that enhance permeability while maintaining separation performance. These new materials, such as polymer blends and ceramic composites, allow for higher flow rates and improved fouling resistance, which are critical for applications in water treatment and food processing.

Additionally, the integration of smart technologies into microfiltration systems is transforming their performance and monitoring capabilities. For instance, the use of IoT (Internet of Things) devices enables real-time monitoring of membrane conditions, providing valuable data for predictive maintenance. This proactive approach reduces downtime and operational costs, showcasing the trend towards automation in filtration processes. As industries continue to embrace these innovations, the future of microfiltration technology looks promising, with ongoing research focused on enhancing efficiency and expanding its applicability to new sectors.

Challenges and Solutions in Microfiltration System Implementation

Microfiltration membrane technology has gained traction in various industries, but its implementation can come with challenges. One significant issue is membrane fouling, where particles and biofilms accumulate on the membrane surface, reducing efficiency. Regular cleaning and maintenance schedules can significantly mitigate fouling, as well as the use of pre-treatment technologies to minimize the load on membranes.

Tip: Incorporate regular monitoring of feed water quality to understand the fouling tendencies of your system. This proactive approach can allow operators to implement targeted pre-treatment measures.

Another challenge is the cost associated with installation and operation. While microfiltration systems offer long-term benefits, the initial investment can deter some users. However, opting for modular systems can help distribute costs over time, allowing for gradual upgrades as budget allows.

Tip: Explore financing options or grants aimed at supporting the adoption of advanced water treatment technologies. This approach can alleviate financial pressures and facilitate smoother implementation.

Microfiltration Membrane Technology Performance Insights

Related Posts

-

Exploring Alternatives to Best Microfiltration Membrane Technology for Enhanced Water Purification

-

7 Compelling Reasons to Choose the Best Side Stream Filtration for Your Heating System

-

The Future of Advanced Vacuum Filtration Solutions

-

Emerging Trends in Best Pulp Industries to Watch for Global Buyers in 2025

-

How to Choose the Right Wood Pulp for Your Paper Production Needs

-

Ultimate Guide to Choosing the Right Bagasse Plate Making Machine for Your Business